December 1, 2023

Skyports Drone Services and Field to revolutionise the utilities, road and rail sectors with greener, smarter, safer asset inspections and insight

Skyports Drone Services and Field announce a new service that gives utility and infrastructure owners and operators rapid and detailed insights into their assets to enable and inform critical decision-making faster, save inspection time and operational costs, improve safety, and reduce carbon footprint. The partnership combines Field’s unrivalled linear infrastructure inspection ecosystem based on Uncrewed Aircraft Systems (UAS) Technology and software developed in Norway with Skyports Drone Services global specialism in Beyond Visual Line of Sight (BVLOS) operations.

The new service, which is available across the UK and Europe, uses Field’s complete drone, sensor, and software solution to conduct aerial inspections and capture mission-critical data. The system instantly captures and transfers data to the cloud with the highest cyber-security standards and supplies on-demand insights, reducing the need for physical inspections and limiting workers’ exposure to potentially hazardous situations.

Field’s complete BVLOS ecosystem has been tested thoroughly, undergoing more than 6500 flight hours under the world’s harshest conditions, from subzero arctic temperatures to extreme desert winds and heat. It’s a robust and complete linear inspection solution. There is no other solution like it on the market,” said Jimmy Bostrom Head of Emerging Markets at Field.

The partnership also represents a revolution in Skyports Drone Services inspection and monitoring capabilities. The company, which applies its strong operational, technical and regulatory expertise to solve complex logistical challenges with drone operations, will operate the Explorer UAS technology for customers across the linear infrastructure sector.

This new service offering not only provides utility and infrastructure owners with rapid and detailed insights into their assets but also facilitates critical decision-making, cuts operational costs, enhances safety, and produces significantly lower emissions than existing solutions said Alex Brown, Director of Skyports Drone Services.

We look forward to making the Field solution available to rail and utilities customers and continuing to demonstrate the value of BVLOS drone operations.

Current asset survey methods for the rail and utilities sector are typically highly manual, relying on labour-intensive single-sensor drone flights flown visual line of sight, or use of helicopters. Field’s multi-sensor payload can complete multiple surveys at one time. Combined with Skyports Drone Services’ flight permissions and experience of long-range BVLOS flight, the new solution will enable up to 100km of linear infrastructure to be surveyed in a single day.

Field and Skyports Drone Services have completed extensive flight testing and have recently launched commercial services with a UK national linear infrastructure company.

Field UAS technology

Field’s in-house developed and produced drones are tailormade for linear inspection with a proven track record with thousands of flight hours in harsh environments. Field’s unique all-in-one sensor captures high-resolution oblique images, thermal images, and LiDAR and Nadir images in parallel, allowing for high efficiency while capturing rich data for infrastructure owners and operators.

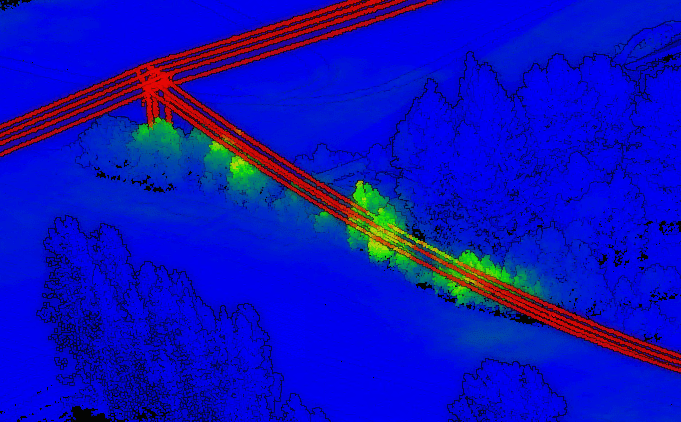

LiDAR AI

Highly accurate colourised LiDAR point clouds using AI to rapidly detect vegetation management issues within two days of data capture. This is a game changer for vegetation management programmes, and has the potential to save time, money and even lives by identifying hidden vegetation collisions with power lines.

Defect Identification

High-res and thermal imagery using AI to identify defects, easily trained by users within the platform. Saves time manually reviewing thousands of survey images, increases detection of defect identification saving time and money in on maintenance programmes, and reducing blackouts with their associated effect on end customers and financial penalties which can be in their Millions.